Table

of Contents Page

2......... Project Information

2.3 Construction

Programme and Activities

2.5 Status of

Environmental Licences, Notification and Permits

3......... Environmental Monitoring Requirements

3.1 Construction Dust

Monitoring

3.2 Construction Noise

Monitoring

4......... Implementation

Status of Environmental Mitigation Measures

5.1 Construction Dust

Monitoring

5.2 Regular

Construction Noise Monitoring

6......... ENVIRONMENTAL

SITE INSPECTION AND AUDIT

7......... Environmental Non-conformance

7.1 Summary of

Monitoring Exceedances

7.2 Summary of

Environmental Non-Compliance

7.3 Summary of

Environmental Complaints

7.4 Summary of

Environmental Summon and Successful Prosecutions

8.1 Construction

Programme for the Next Three Months

8.2 Key Issues for the

Coming Month

8.3 Monitoring

Schedule for the Coming Month

9......... ConclusionS AND

RECOMMENDATIONS

List

of Tables

Table 2.1........... Construction

Activities in the reporting month

Table 2.2........... Contact Information of Key Personnel

Table 2.3........... Status of Environmental Licenses, Notifications and Permits

Table 3.1 ......... Air Quality Monitoring Equipment

Table 3.2 ......... Location of Construction Dust Monitoring Station

Table 3.3 ......... Noise

Monitoring Parameters, Frequency and Duration

Table 3.4 ......... Noise Monitoring Equipment for Regular Noise Monitoring

Table 3.5 ......... Noise

Monitoring Stations during Construction Phase

Table 3.6 ......... Noise

Monitoring Parameters, Frequency and Duration

Table 4.1........... Status of Required

Submission under Environmental Permit

Table 5.1 ......... Summary of

24-hour TSP Monitoring Result in the Reporting Period

Table 5.2 ......... Summary of

1-hour TSP Monitoring Result in the Reporting Period

Table 5.3 ......... Summary of

Construction Noise Monitoring Results in the Reporting Period

Table 6.1 ......... Observations

and Recommendations of Site Audit

Table 8.1........... Construction

Activities in the coming three months

List of Figures

|

Site Layout Plan |

|

|

Location of Air

Quality Monitoring Station |

|

|

Locations of Noise

Monitoring Station |

List

of Appendices

|

Construction Programme |

|

|

Project

Organization Structure |

|

|

Implementation Schedule

of Environmental Mitigation Measures |

|

|

Summary of Action

and Limit Levels |

|

|

Calibration

Certificates of Equipment |

|

|

EM&A Monitoring

Schedules |

|

|

Air Quality

Monitoring Results and their Graphical Presentations |

|

|

Noise Monitoring

Results and their Graphical Presentations |

|

|

Event and Action

Plan |

|

|

Cumulative

Statistics on Complaints, Notification of Summons and Successful Prosecutions

|

|

|

Monthly Summary

Waste Flow Table |

Central Kowloon Route – Kai Tak West (CKR-KTW; Contract No. HY/2014/07)

(hereafter called “the Project”) covers part of the construction of the Central

Kowloon Route (CKR).

The Project comprises

the follow works:

·

50x30m access shaft with noise enclosure

at Ma Tau Kok (MTK);

·

100m long cut-and-cover (C&C) tunnel

at MTK;

·

Demolition and re-provisioning of MTK

Public Pier;

·

160m long underwater tunnel (UWT) (Stage 1);

·

210m long UWT (Stage 2);

·

60m long C&C tunnel at Kai Tak;

·

130m long depressed road and 200m long

underpass at Kai Tak;

·

390m long underground tunnel ventilation

audit at Kai Tak;

·

Seawall demolition and construction of new

landing steps; and

·

Barging Point enclosure and conveyor

system.

The EM&A programme commenced on 4 April 2018.The impact EM&A for the Project includes

air quality and noise monitoring.

This is the 80th

monthly EM&A Report presenting the EM&A works carried out during the

period between 1 and 30 November 2024. As informed by the Contractor, major

activities in the reporting period were:

|

Locations |

Site Activities |

|

Kai Tak |

- Defect rectification works at

underpass, depressed road and C&C |

|

Ma Tau Kok |

- Temporary traffic management (TTM) implementation; |

|

Kowloon Bay |

- Removal of Excavation and

Lateral Support (ELS) at Stage 2 UWT; |

Breaches

of Action and Limit Levels for Air Quality

All

24-hour TSP result was below the Action and Limit Levels at all monitoring

locations in the reporting month.

All

1-hour TSP result was below the Action and Limit Levels at all monitoring

locations in the reporting month.

Breaches

of Action and Limit Levels for Noise

Regular

Noise Monitoring

No exceedance of Action and Limit level of

noise was recorded in the reporting month.

Complaint,

Notification of Summons and Successful Prosecution

One (1) complaint was received in the reporting month (November 2024).

The complaint was investigated and have been provided in this reporting month

(November 2024).

Reporting

Changes

No report changes in the reporting period.

Future

Key Issues

Key issues to be

considered in the next three months included:

|

Locations |

Site Activities |

|

Kai Tak |

- Defect rectification works at

underpass, depressed road and C&C |

|

Ma Tau Kok |

- TTM implementation; |

|

Kowloon Bay |

- Removal of Excavation and

Lateral Support (ELS) at Stage 2 UWT; |

· Section 1: Introduction

· Section 2: Project Information

· Section 3: Environmental Monitoring Requirement

· Section 4: Implementation Status of Environmental Mitigation Measures

· Section 5: Monitoring Results

· Section 6: Environmental Site Inspection and Audit

· Section 7: Environmental Non-conformance

· Section 8: Future Key Issues

· Section 9: Conclusions and Recommendations

(a)

construction of approximately 160m long

cut-and-cover tunnel and 370m long underwater tunnel between the tunnel section

at Ma Tau Kok and the depressed road of the CKR within Kai Tak Development;

(b)

reconstruction of the seawall at Ma Tau

Kok public pier, and the sloping seawall at the Former Kai Tak Airport Runway;

(c)

construction of approximately 125m long

depressed road and 200m long underpass of the CKR within Kai Tak Development;

(d)

construction of approximately 360m long

underground tunnel ventilation adit of the CKR;

(e)

reconstruction of Kowloon City Ferry

Pier Public Transport Interchange; and

(f)

other associated works.

Table 2.1 Construction Activities in the reporting month

|

Locations |

Site Activities |

|

Kai

Tak |

-

Defect rectification works at underpass, depressed road and C&C |

|

Ma

Tau Kok |

- Temporary

traffic management (TTM) implementation; |

|

Kowloon

Bay |

-

Removal of Excavation and Lateral Support (ELS) at Stage 2 UWT; |

Table 2.2 Contact Information of Key Personnel

|

Party |

Role |

Position |

Name |

Telephone |

Fax |

|

Arup-Mott

MacDonald Joint Venture |

Residential

Engineer (ER) |

Engineer’s Representative |

Mr. Patrick Lo |

36195901 |

2268 3954 |

|

ERM |

Independent

Environmental Checker (IEC) |

Independent

Environmental Checker |

Ms. Mandy To |

2271 3113 |

3015 8052 |

|

Gammon |

Contractor |

Contracts Manager |

Mr. Kin Fai Tam |

2516 8823 |

2516 6260 |

|

Environmental Manager |

Ms. Michelle Tang |

9267 8866 |

2516 6260 |

||

|

AECOM |

Contractor’s

Environmental Team (ET) |

ET Leader |

Mr. Y. W. Fung |

3856 5681 |

2317 7609 |

Table 2.3 Status of Environmental Licenses, Notifications and Permits

|

Permit / License No. / Notification/

Reference No. |

Valid Period |

Status |

Remarks |

|

|

From |

To |

|||

|

Further Environmental Permit |

||||

|

FEP-01/457/2013/C |

28 Feb 2018 |

End of Project |

Valid |

-- |

|

Wastewater Discharge License |

||||

|

WT00043692-2023 |

1 Apr 2023 |

31 Mar 2028 |

Valid |

Ma Tau Kok |

|

WT00043881-2023 |

30 Jun 2023 |

30 Jun 2028 |

Valid |

Underwater Tunnel Stage 2 |

|

WT00044013-2023 |

1 May 2023 |

30 Apr 2028 |

Valid |

Kai Tak and Underwater Tunnel Stage 1 |

|

Construction Noise Permit |

||||

|

GW-RE0618-24 |

1 Jun 2024 |

30 Nov 2024 |

Valid |

General Works at Ma Tau Kok |

|

GW-RE1173-24 |

1 Oct 2024 |

31 Mar 2025 |

Valid |

General Works at Kai Tak |

|

GW-RE1300-24 |

21 Oct 2024 |

20 Apr 2025 |

Valid |

General Works at Promenade |

|

GW-RE0585-24 GW-RE1423-24 |

19 May 2024 19 Nov 2024 |

18 Nov 2024 18 May 2025 |

Expired Valid |

General Works at Stage 1 Underwater Tunnel |

|

GW-RE0627-24 |

7 Jun 2024 |

6 Dec 2024 |

Valid |

General Works at Stage 2 Underwater Tunnel |

|

GW-RE1149-24 |

19 Sep 2024 |

18 Mar 2025 |

Valid |

Kai Tak Access Road |

|

Chemical

Waste Producer Registration |

||||

|

5118-247-G2347-47 |

30 Jan 2018 |

End of Project |

Valid |

-- |

|

5118-247-G2347-48 |

30 Jan 2018 |

End of Project |

Valid |

-- |

|

Marine Dumping Permit |

||||

|

-- |

-- |

-- |

-- |

-- |

|

Billing Account for Construction

Waste Disposal |

||||

|

7029909 |

22 Jan 2018 |

End of Project |

Account Active |

-- |

|

Notification Under Air Pollution

Control (Construction Dust) Regulation |

||||

|

429442 |

5 Jan 2018 |

5 Jul 2025 |

Notified |

-- |

|

|

||||

Monitoring Requirements

Monitoring Equipment

Table 3.1 Air Quality Monitoring Equipment

|

Tisch

Total Suspended Particulate Mass Flow Controlled High Volume Air Sampler |

|

|

Calibration

Kit (24-hour

TSP) |

TISCH

Environmental Orifice |

|

Portable

direct reading dust meter |

Sibata Digital Dust Monitor |

Monitoring Locations

Table 3.2 Location of Construction Dust Monitoring Station

|

Location |

Monitoring Station |

Description |

|

E-A14a

[1] |

Block

B of Merit Industrial Centre |

Rooftop

(13/F) |

[1] The air monitoring station proposed in the

EM&A Manual (i.e. Wyler Gardens with ID: E-A14) was not available for

impact dust monitoring, therefore impact monitoring was conducted at E-A14a as

an alternative which was agreed by the ER, IEC and EPD.

Monitoring

Methodology

(a)

The HVS was

installed in the vicinity of the air sensitive receivers. The following criteria were considered in the

installation of the

HVS as far as practicable: -

(i)

A horizontal platform with appropriate

support to secure the sampler against gusty wind was provided.

(ii)

Two samplers should

not be placed less than 2m apart from each other;

(iii)

The distance between the HVS and

any obstacles, such as buildings, was at least twice the height that the

obstacle protrudes above the HVS.

(iv)

A minimum of 2 meters separation

from walls, parapets and penthouse for rooftop sampler.

(v)

A minimum of 2 meters separation from

any supporting structure, measured horizontally is required.

(vi)

No furnace or incinerator flues

nearby.

(vii)

Airflow around the sampler was

unrestricted.

(viii)

The sampler was located more than

20 meters from any dripline.

(ix)

Any wire fence and gate, required

to protect the sampler, did not obstruct the monitoring process.

(x)

Permission was obtained to set up

the samplers and access to the monitoring station.

(xi)

A secured supply of electricity

was obtained to operate the sampler.

(b)

Preparation of

Filter Papers

(i)

Glass fibre filters, G810 were

labelled and sufficient filters that were clean and without pinholes were

selected.

(ii)

All filters were equilibrated in

the conditioning environment for 24 hours before weighing. The conditioning

environment temperature was around 25 °C and not variable by more than ±3 °C;

the relative humidity (RH) was < 50% and not variable by more than ±5%. A

convenient working RH was 40%.

(iii)

All filter papers were prepared

and analysed by ALS Technichem

(HK) Pty Ltd., which is a HOKLAS accredited laboratory and has comprehensive quality assurance and quality control programmes.

(c)

Field

Monitoring

(i)

The power supply was checked to ensure the HVS works properly.

(ii)

The filter holder and the area

surrounding the filter were cleaned.

(iii)

The filter holder was removed by

loosening the four bolts and a new filter, with stamped number upward, on a

supporting screen was aligned carefully.

(iv)

The filter was properly aligned

on the screen so that the gasket formed an airtight seal on the outer edges of

the filter.

(v)

The swing bolts were fastened to

hold the filter holder down to the frame. The pressure applied was sufficient

to avoid air leakage at the edges.

(vi)

Then the shelter lid was closed

and was secured with the aluminium strip.

(vii)

The HVS was warmed-up for about 5

minutes to establish run-temperature conditions.

(viii)

A new flow rate record sheet was

set into the flow recorder.

(ix)

On site temperature and atmospheric

pressure readings were taken and the flow rate of the HVS was checked and

adjusted at around 1.3 m3/min, and complied

with the range specified in the EM&A Manual (i.e. 0.6-1.7 m3/min).

(x)

The programmable digital timer

was set for a sampling period of 24 hrs, and the starting time, weather

condition and the filter number were recorded.

(xi)

The initial elapsed time was

recorded.

(xii)

At the end of sampling, on site

temperature and atmospheric pressure readings were taken and the final flow

rate of the HVS was checked and recorded.

(xiii)

The final elapsed time was

recorded.

(xiv)

The sampled filter was removed

carefully and folded in half length so that only

surfaces with collected particulate matter were in contact.

(xv)

It was then placed in a clean

envelope and sealed.

(xvi)

All monitoring information was

recorded on a standard data sheet.

(xvii) Filters were then sent to ALS Technichem (HK) Pty Ltd. for analysis.

(d)

Maintenance and

Calibration

(i)

The HVS and its accessories were maintained in good working condition, such as

replacing motor brushes routinely and checking electrical wiring to ensure a

continuous power supply.

(ii)

HVSs were calibrated using

TE-5025A Calibration Kit upon installation and thereafter at bi-monthly

intervals.

(iii)

Calibration certificate of the TE-5025A Calibration Kit and the HVSs are provided in Appendix E.

(a)

Measuring Procedures

The measuring procedures of the 1-hour dust meter are in accordance with

the Manufacturer’s Instruction Manual as follows:

(i)

Turn the power on.

(ii)

Close the air collecting opening cover.

(iii)

Push the “TIME SETTING” switch to [BG]

(iv)

Push “START/STOP”

switch to perform background measurement for 6 seconds.

(v)

Turn the knob at SENSI ADJ position to insert

the light scattering plate.

(vi)

Leave the equipment for 1 minute upon “SPAN

CHECK” is indicated in the display.

(vii)

Push “START/STOP” switch to perform automatic

sensitivity adjustment. This measurement takes 1 minute.

(viii)

Pull out the knob and return it to MEASURE

position.

(ix)

Push the “TIME SETTING” switch the time set

in the display to 3 hours.

(x)

Lower down the air collection opening cover.

(xi)

Push “START/STOP” switch to start

measurement.

(b)

Maintenance and Calibration

(i)

The 1-hour TSP meter was

calibrated at 1-year intervals against a High Volume

Samplers. Calibration certificates of the Laser Dust Monitors are provided in Appendix E.

Monitoring Schedule for the

Reporting Month

Monitoring Requirements

Table 3.3 Noise Monitoring Parameters, Frequency and Duration

|

Parameter and Duration |

Frequency |

|

30-mins

measurement at each monitoring station between 0700 and 1900 on normal

weekdays. Leq, L10 and L90

would be recorded. |

At least once per week |

Table 3.4 Noise Monitoring Equipment for Regular Noise Monitoring

|

B&K (Model No. 2250 & 2250L) |

|

|

Acoustic

Calibrator |

B&K (Model

No. 4231) Rion(Model

No. NC-74) MVI(Model

No. CAL21) |

Monitoring Locations

Table 3.5 Noise Monitoring Stations during Construction Phase

|

Location |

Monitoring Station |

Description |

Measurement |

|

E-N12a [1] |

19 Hing Yan Street |

Rooftop (9/F) |

Façade |

|

E-N21a [1] |

Block B of Merit Industrial Centre |

Rooftop (13/F) |

Free field[2] |

Notes:

[1] The noise monitoring stations proposed in the EM&A Manual

(i.e. Grand Waterfront Tower 3 with ID: E-N12 and Hang Chien Court Block J with

ID: E-N21) were not available for impact noise monitoring, therefore impact

monitoring was conducted at E-N12a and E-N21a as an alternative which was

agreed by the ER, IEC and EPD.

[2] A correction of +3 dB(A)

was made to the free field measurements.

Monitoring Parameters, Frequency and Duration

Table 3.6 Noise Monitoring Parameters, Frequency and Duration

|

Location |

Parameter and Duration |

Frequency |

|

E-N12a

and E-N21a |

30-mins measurement at each monitoring

station between 0700 and 1900 on normal weekdays. Leq,

L10 and L90 would be recorded. |

At

least once per week |

Monitoring Methodology

(a)

The sound level meter was set on

a tripod at a height of 1.2 m above the ground.

(b)

Façade measurement was made at

E-N12a.

(c)

Free field measurements was made at monitoring location E-N21a. A correction of +3

dB(A) shall be made to the free field measurements.

(d)

The battery condition was checked to ensure the correct

functioning of the meter.

(e)

Parameters such as frequency

weighting, the time weighting and the measurement time were set as follows:

(i)

frequency weighting

(ii)

time weighting: Fast

(iii)

time measurement: Leq(30-minutes) during non-restricted

hours i.e. 0700 – 1900 on normal weekdays.

(f)

Prior to and after each noise

measurement, the meter was calibrated using the acoustic calibrator for 94

dB(A) at 1000 Hz. If the difference in

the calibration level before and after measurement was more than 1 dB(A), the

measurement would be considered invalid and repeat of noise measurement would

be required after re-calibration or repair of the equipment.

(g)

During the monitoring period, the

Leq, L10 and L90

were recorded. In addition, site

conditions and noise sources were recorded on a standard record sheet.

(h)

Noise measurement was paused

during periods of high intrusive noise (e.g. dog barking, helicopter noise) if

possible. Observations were recorded when intrusive noise was unavoidable.

(i)

Noise monitoring was cancelled in

the presence of fog, rain, wind with a steady speed exceeding 5m/s, or wind

with gusts exceeding 10m/s.

(a)

The microphone

head of the sound level meter was cleaned with soft cloth at

regular intervals.

(b)

The meter and

calibrator were sent to the supplier or HOKLAS laboratory to check and

calibrate at yearly intervals.

(c)

Calibration

certificates of the sound level meters and acoustic

calibrators are provided in Appendix E.

Monitoring

Schedule for the Reporting Month

Table 4.1 Status of Required Submission under Environmental Permit

|

EP Condition |

Submission |

Submission

Date |

|

Condition 3.4 of |

Monthly EM&A Report for October

2024 |

14 November 2024 |

Table 5.1 Summary of 24-hour

TSP Monitoring Result in the Reporting Period

|

ID |

Average (mg/m3) |

Range (mg/m3) |

Action Level (mg/m3) |

Limit Level (mg/m3) |

|

E-A14a |

42.2 |

26.0 - 60.8 |

197.3 |

260 |

Table 5.2 Summary of 1-hour TSP Monitoring Result in the Reporting Period

|

ID |

Average (mg/m3) |

Range (mg/m3) |

Action Level (mg/m3) |

Limit Level (mg/m3) |

|

E-A14a |

61.1 |

57.7 – 63.5 |

302.4 |

500 |

Table 5.3 Summary of Construction Noise Monitoring Results in the Reporting Period

|

ID |

Range, dB(A), Leq (30 mins) |

Limit Level, dB(A), Leq (30 mins) |

|

E-N12a |

62.9 – 64.2 |

75 |

|

E-N21a |

58.0

– 58.6 |

75 |

Table 6.1 Observations and Recommendations of Site Audit

|

Parameters |

Date |

Observations and Recommendations |

Follow-up |

|

Air Quality |

6

November 2024 |

Reminder: The contractor

was reminded to provide watering at MTK site regularly. |

The

item was rectified by the Contractor on |

|

Noise |

Nil |

Nil |

Nil |

|

Water Quality |

20

November 2024 |

Observation: The silt curtain

was observed not fully enclosed at Kai Tak Promenade. The Contractor should

ensure the silt curtain was fully enclosed to prevent marine pullution. |

The

item was rectified by the Contractor on |

|

Waste/ Chemical Management |

20

November 2024 |

Reminder: The

Contractor was reminded to provide dirp tray for the chemical container at

Stage 2 marine platform. |

The

item was rectified by the Contractor on |

|

27

November 2024 |

Reminder: The

Contractor was reminded to provide a cover for the general refuse container

at Stage 2 marine platform. |

The

item was rectified by the Contractor on |

|

|

Landscape & Visual |

Nil |

Nil |

Nil |

|

Permits/ Licenses |

Nil |

Nil |

Nil |

*The

item was under rectification on last reporting month.

Table 8.1 Construction Activities in the coming three months

|

Locations |

Site Activities |

|

Kai

Tak |

-

Defect rectification works at underpass, depressed road and C&C |

|

Ma

Tau Kok |

-

TTM implementation; |

|

Kowloon

Bay |

-

Removal of Excavation and Lateral Support (ELS) at Stage 2 UWT; |

Document control record

Document prepared

by:

Unit 1608, 16/F, Tower B,

Manulife Financial Centre

223 -231 Wai Yip Street, Kwun Tong, Kowloon,

Hong Kong.

|

T |

3664 6888 |

A person using

a)

Using

the documents or data in electronic form without requesting and checking them

for accuracy

b)

Using

the documents or data for any purpose not agreed to in writing by

c)

against

the original hard copy version.

3 Air

Quality and Noise Monitoring

6 Summary of

Complaints, Notification of Summons and Prosecutions

9 Conclusion

and Recommendations

Appendices

Appendix A Alignment and Works Site in Kai Tak West

Area for the Contract No. HY/2023/08

Appendix B Construction

Programme

Appendix C Project Organization Chart

Appendix D Event and Action Plan (EAP) (Air Quality Monitoring)

Appendix E Event

and Action Plan (EAP) (Noise Monitoring)

Appendix F Environmental

Mitigation Implementation Schedule (EMIS)

Appendix G Waste

Flow Table

Appendix H Statistics

on Complaint, Notifications of Summons and Successful Prosecutions

1.1.1

Build King - Lee Tung Joint Venture

(“Contractor”) commenced the construction works of Highway Department (HyD)

Central Kowloon Route Contract No. HY/2023/08 – Central Kowloon Route –

Remaining Works at Kai Tak West Area (“The Project”) on 11

November 2024.

This is the 1st

monthly Environmental Monitoring and Audit (EM&A) report presenting the

EM&A works carried out in the Kai Tak West Area during the period from 11

November 2024 to 30 November 2024.

1.1.2

A summary of major construction

activities informed by the Contractor for the Project during the reporting

period is presented below.

|

Construction Activities Undertaken in Kai Tak West

Area |

|

·

Site preparation and access set up for Part of Site 4C at

Kai Tak Phase 2B Landscape Deck |

Environmental Monitoring and Audit Works

1.1.3

Regular construction air quality monitoring (24-hour TSP and 1-hour

TSP) and noise monitoring works in Kai Tak West Area are currently covered

under the Contract No. HY/2014/07 – Central Kowloon Route – Kai Tak West. The details of the monitoring works could be

referred to Sections 3 and 5 of the corresponding Monthly EM&A Report for

Contract No. HY/2014/07.

1.1.4

Joint weekly site inspections were conducted by representatives

of the Environmental team (ET), the Contractor and the Engineer on 15, 22 and 29 November 2024. A joint site inspection with

the Independent Environmental Checker (IEC) was undertaken on 15 November 2024. Bi-weekly inspection of the implementation of

landscape and visual mitigation measures was conducted by the ET on 15 and 29 November 2024. Details of the audit

findings and implementation status are presented in Section 7. Details of waste management are presented in Section

4.

1.1.5

A summary of the non-compliance (exceedance) during the

reporting period is provided below.

-

No Action / Limit Level exceedance for 1-hour TSP was

recorded.

-

No Action / Limit Level exceedance for 24-hour TSP was recorded.

-

No Action / Limit Level exceedance for construction noise was

recorded.

Complaints, Notification of Summons and Successful Prosecution

1.1.6

No environmental related complaints, notification of summons and

successful prosecution were received in the reporting period.

Reporting Changes

1.1.7

There were no reporting changes during the reporting period.

Future Key Issues

1.1.8

A summary of construction activities informed by the Contractor for

the next reporting period are listed below:

|

Construction

Activities Undertaken in Kai Tak West Area |

|

·

To complete site preparation works and site survey at Kai

Tak Phase 2B Landscaped Deck |

1.1.1

Central Kowloon Route (CKR) is a 4.7 km long dual 3-lane trunk

road in Central Kowloon linking Yau Ma Tei Interchange in West Kowloon with the

road network on Kai Tak Development and Kowloon Bay in East Kowloon.

1.1.2

The Central Kowloon Route – Design and Construction

Environmental Impact Assessment Report (Register No.: AEIAR-171/2013) was

approved with conditions by the Environmental Protection Department (EPD) on 11

July 2013. An Environmental Permit (EP 457/2013) was issued on 9 August 2013. Variations of EP (VEP)

was subsequently applied for and the latest EP (EP-457/2013/D) was issued by

EPD on 15 June 2021.

1.1.3

The construction of the CKR had been divided into different

sections. Contract No. HY/2023/08 – Central Kowloon

Route – Remaining Works covers part of the construction activities located at

Kai Tak West Area and Yau Ma Tei Area under the EP, including:

1.1.4

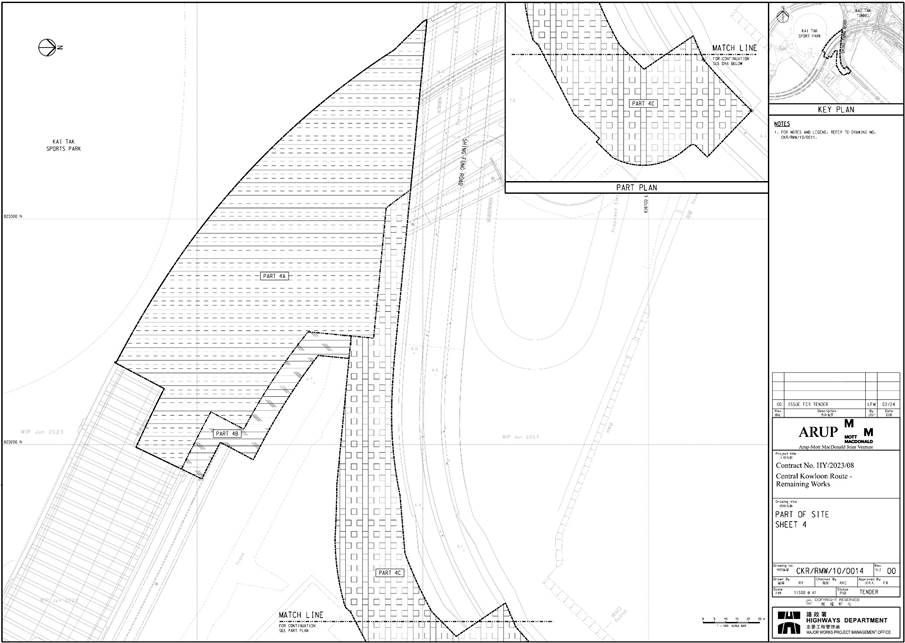

The works site at Kai Tak West Area for the Contract No.

HY/2023/08 are shown in Appendix A.

1.2 Purpose of the Report

1.2.1

This is the 1st monthly Environmental Monitoring and

Audit (EM&A) report presenting the EM&A works carried out for the

Project in the Kai Tak West Area during the period from 11 November 2024 to 30

November 2024.

1.3 Construction Activities Undertaken During the Reporting Period

1.3.1

A summary of major construction activities carried out during

the reporting period are presented in Table 1.1. The construction

programme is presented in Appendix B.

Table 1.1 Summary of Construction Activities during

the Reporting Period

|

Construction

Activities Undertaken in Kai Tak West Area |

Progress |

|

·

Site preparation and access set up for Part of Site 4C at

Kai Tak Phase 2B Landscaped Deck |

10% |

1.4 Project Organisation

1.4.1

The project organization structure is shown in Appendix C.

The key personnel contact names and numbers for the Project are summarized in Table 1.2.

Table 1.2 Contact

Information of Key Personnel

|

Party |

Role |

Position |

Name |

Contact

No. |

|

Arup – Mott MacDonald Joint Venture |

Engineer’s Representative (“ER”) |

Resident Engineer

(Environmental) |

Ms. Jim Li |

9120 1157 |

|

ERM – Hong Long Limited |

Independent Environmental Checker (“IEC”) |

IEC |

Ms. Mandy To |

2271 3313 |

|

Aurecon Hong Kong Limited |

Environmental Team (“ET”) |

ET Leader |

Mr. F. C. Tsang |

2698 6833 |

|

Build King – Tung Lee Joint Venture |

Contractor |

Environmental Officer |

Mr. Samuel Pang |

9876 9121 |

1.5 Status of Environmental

Licences, Notification and Permit

1.5.1

A summary of the valid permits, licences, and /or notifications

on environmental protection for this Project is presented in Table 1.3.

Table 1.3 Summary

of the Environmental Licence, Notification, Permit and Documentations

|

Permit/ License/ Notification / Reference No. |

Valid Period |

Status |

Remark |

|

|

From |

To |

|

|

|

|

Environmental Permit |

||||

|

EP-457/2013/D |

15 June 2021 |

-- |

Valid |

-- |

|

Wastewater Discharge License |

||||

|

-- |

-- |

-- |

To be applied |

-- |

|

Notification of Construction Works Under

the Air Pollution Control (Construction Dust Regulation) |

||||

|

10007346 |

-- |

-- |

Application submitted on 25 July 2024 |

-- |

|

Chemical Waste Producer Registration |

||||

|

5213-252-B2767-01 |

14 August 2024 |

-- |

Valid |

-- |

|

Billing Account for Disposal of

Construction Waste |

||||

|

7051793 |

6 August 2024 |

-- |

Valid |

-- |

|

Y-Park Membership |

||||

|

C0280 |

12 August 2024 |

-- |

Valid |

-- |

|

Construction Nosie Permit |

||||

|

2142643 |

-- |

-- |

Application submitted on 18 Nov 2024 |

General Activities at Kai Tak Phase 2B

Landscaped Deck |

2.1 Environmental Permit (EP) Submission Status

2.2 Environmental permit (EP)

conditions under the EIAO, submission status under the EP and implementation

status of mitigation measures had been reviewed and implemented on schedule.

The status of required submissions under the EP (EP-457/2013/D) as of the reporting

period for the Project are summarised in Table 2.1.

Table 2.1 Summary of Status of Required Submission for EP-457/2013/D for the

Project

|

EP Condition |

Submission |

Submission

Date |

|

1.12 |

Notification of Commencement Date of Construction of

Project |

11 September 2024 |

|

2.3 |

Community Liaison Group |

Covered by other Contracts |

|

2.4 |

Management Organization of the main construction companies |

11 September 2024 |

|

2.5 |

Construction Programme and EPD Submission Schedule |

11 September 2024 |

|

2.6 |

Design Drawing |

11 September 2024 |

|

2.8 |

Landscape Mitigation Plan (LMP) (Version 1) |

11 September 2024 |

|

2.9 |

Construction Noise Mitigation Plan (CNMMP) (Version 1) |

11 September 2024 |

|

3.3 |

Baseline Monitoring Report |

(1) |

Notes:

(1)

The Baseline Monitoring Report for Contract No. HY/2014/07 Kai

Tak West will be adopted for the Kai Tak West Area of this Project.

3

Air Quality and Noise Monitoring

3.1 Air Quality

Monitoring Requirements and

Results

3.1.1

As the air quality (24-hour TSP, 1-hour TSP) monitoring works in

Kai Tak West Area are currently covered under Contract No. HY/2014/07 – Central

Kowloon Route – Kai Tak West. The

details of the corresponding monitoring parameters, equipment, methodology,

monitoring schedule wind data, results and the established Action and Limit

Levels could be referred to Sections 3 and 5 of the corresponding Monthly EM&A

Report for Contract No. HY/2014/07.

Observations

3.1.2

No Action/Limit Level exceedance was recorded for all 1-hour TSP

and 24-hour TSP monitoring in the reporting period.

3.1.3

Site audits were carried out on a weekly basis to monitor and

audit the timely implementation of air quality mitigation measures within the

site boundaries of this Project. A summary

of observation during the site audits is shown in Table 7.1 of this report.

3.2 Noise

Monitoring

Requirements and Results

3.2.1

As the construction noise monitoring works in Kai Tak West Area

are currently covered under Contract No. HY/2014/07 – Central Kowloon Route –

Kai Tak West. The details of the

corresponding monitoring parameters, equipment, methodology, results and the

established Action and Limit Levels could be referred to Sections 3 and 5 of

the corresponding Monthly EM&A Report for Contract No. HY/2014/07.

Observations

3.2.2

No Action/Limit Level exceedance was recorded for construction

noise monitoring in the reporting period.

3.2.3

Site audits were carried out on a weekly basis to monitor and

audit the timely implementation of noise mitigation measures within the site

boundaries of this Project. A summary of

observations during the site audits is shown in Table 7.1 of this report.

4

Waste Management

4.1.1

Waste generated from this Project includes inert C&D

materials and non-inert C&D materials. Non-inert C&D materials are made

up of general refuse, vegetative wastes and recyclable wastes such as plastics

and paper/cardboard packaging waste. Steel materials generated from the project

are also grouped into non-inert C&D materials as the materials were not

disposed of with other inert C&D materials. As advised by the Contractor, no

inert C&D materials, non-inert C&D materials nor chemical waste was

generated and disposed of during this reporting period.

4.1.2

With reference to relevant handling records and trip tickets of

this Project, the quantities of different types of waste generated in the

reporting period are summarised in Table 4.1. Details of cumulative waste management data are presented as a

waste flow table in Appendix G.

Table 4.1 Quantities of Waste Generated

from the Project in the Reporting Period

|

Reporting period |

Quantity |

|||||

|

Inert

C&D Materials (in

‘000 kg) |

Chemical

Waste (in

‘kg) |

Non-inert

C&D Materials |

||||

|

Others, e.g. General Refuse disposed at

Landfill (in

‘000kg) |

Recycled

materials |

|||||

|

Paper/ cardboard (in

‘000kg) |

Plastics (in

‘000 kg) |

Metals (in

‘000 kg) |

||||

|

Nov 2024 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

0.00 |

5.1.1

As per the EM&A Manuals, the landscape and visual mitigation

measures shall be implemented, and site inspections should be undertaken once

every two weeks during the construction period.

5.1.2

Bi-weekly inspection of the implementation of landscape and

visual mitigation measures was conducted on 15 and 29 November 2024. The observations and

recommendations made during the site inspections are presented in Table 7.1. A summary of the implementation status is

presented in Appendix F.

6

Summary of Complaints, Notification of

Summons and Prosecutions

6.1.1

The environmental Complaints Handling Procedures is shown in

below.

|

Complaint Received via Project Hotline |

Complaint Received via 1823 or from other government

departments |

||||

|

|

|

|

|

||

|

Contractor notify ER, ET and IEC |

ER notify Contractor, ET and IEC |

||||

|

|

|

|

|

||

|

Contractor log complaint and date of receipt onto the complaint

database. Contractor, ER and

ET to conduct investigation of complaint |

|||||

|

|

|

|

|

||

|

If complaint is considered not valid |

If complaint is found valid |

||||

|

|

|

|

|

||

|

ET or ER to reply the

complainant if necessary |

Contractor to identify and implement remedial

measures in consultation with the IEC, ET and ER. |

||||

|

|

|

|

|

||

|

|

|

The ER, ET and IEC to review the

effectiveness of the Contractor’s remedial measures and the updated

situation; ET to undertake additional monitoring and audit to verify the

situation if necessary and oversee that circumstances leading to the

complaint do not recur. ER to conduct further inspection as necessary.

|

|||

|

|

|

|

|

||

|

If the complaint is referred by the EPD, the Contractor to

prepare interim report on the status of the complaint investigation and

follow-up actions stipulated above, including the details of the remedial

measures and additional monitoring identified or already taken, for

submission to EPD within the time frame assigned by the EPD. |

|||||

|

|

|

|

|||

|

The ET to record the details of the complaint, results of the

investigation, subsequent actions taken to address the complaint and updated

situation including the effectiveness of the remedial measures, supported by

regular and additional monitoring results in the monthly EM&A reports. |

|||||

6.1.2

Should non-compliance of the criteria occur, action in

accordance with the Event and Action Plan in Appendix D and Appendix

E shall be carried out.

6.1.3

No exceedance of the Action and Limit Levels of air quality (1-hour

TSP and 24-hour TSP) monitoring and noise monitoring was recorded in the

reporting period.

6.1.4

No complaint was received in the reporting period.

6.1.5

No non-compliance was received in the reporting period.

6.1.6

No notification of summons and successful prosecution was

received in the reporting period.

6.1.7

Statistics on complaints, notifications of summons and

successful prosecutions are summarized in Appendix H.

7.1.1

Site inspections were carried out on a weekly basis to monitor

the implementation of proper environmental pollution control and mitigation

measures under the Contract. In the reporting period,

3 site inspections were carried out by the

representative of ET, Contractor and Engineer on 15, 22 and 29 November

2024, along with bi-weekly inspection of the

implementation of landscape and visual mitigation measures conducted on 15

and 29 November 2024.

7.1.2

One joint site inspection with the IEC was also undertaken on 15

September 2024. No deficiencies were observed

during weekly site inspection. Key observations during the site inspections are

summarized in Table 7.1.

Table 7.1 Summary of Site

Observation

|

Date |

Environmental

Observations |

Follow-up

Status |

|

15 November 2024 |

Nil. |

Nil. |

|

22 November 2024 |

Nil. |

Nil. |

|

29 November 2024 |

Nil. |

Nil. |

7.1.3

No observation was identified during the environmental site

inspection in the reporting period.

7.1.4

According to the EIA Study Report, Environmental Permit,

contract documents and EM&A Manual, the mitigation measures detailed in the

documents had been implemented as much as practical during the reporting

period. An updated Implementation Status of Environmental Mitigation Measures

(EMIS) is provided in Appendix F.

8.1.1

The construction activities to be undertaken in the next

reporting period are listed below:

|

Construction

Activities Undertaken in Kai Tak West Area |

|

·

To complete site preparation works and site survey at Kai

Tak Phase 2B Landscaped Deck |

8.1.2

Potential environmental impacts arising from the above

construction activities are mainly associated with dust and waste management.

8.1.3

The tentative schedule of air quality (1-hour TSP and 24-hour

TSP) monitoring and noise monitoring in the next reporting period is presented

in Appendix F of the corresponding Monthly EM&A Report for Contract No.

HY/2014/07.

8.1.4

The construction programme for the Project for the next

reporting period is presented in Appendix B.

9

Conclusion and Recommendations

9.1.1

This is the 1st monthly EM&A Report presents the EM&A works undertaken

in Kai Tak West Area during the period from 11 November 2024 to 30 November 2024 in accordance with the EM&A Manual and the requirement under

EP-457/2013/D.

9.1.2

Air quality monitoring (including 1-hour TSP and 24-hour TSP) and

noise monitoring were carried out in the reporting period under Contractor No. HY/2014/07.

No exceedance of the Action and Limit

Level was recorded for air quality monitoring and noise during the reporting period.

9.1.3

Weekly environmental site inspections by the representative of

ET, Contractor and Engineer were conducted during the reporting period. One

joint site inspection with the IEC was carried out on 15 November 2024. No observation was

identified during the reporting period. The environmental performance of the

Project was therefore considered satisfactory.

9.1.4

No complaint was received in the reporting period.

9.1.5

No non-compliance situation was received in the reporting period.

9.1.6

No notification of summons or prosecution was received since

commencement of the Contract.

9.1.7

The ET will keep track on the construction works to confirm

compliance of environmental requirements and the proper implementation of all

necessary mitigation measures.

Appendix A

Alignment and Works Site in Kai Tak West Area for the

Contract No. HY/2023/08

Kai Tak Phase

2B Landscaped Deck

Appendix B

Construction Programme

Appendix C

Project

Organisation Chart

TSANG Fan

Cheong Tel.: 3664 6801

Appendix

D

Event

and Action plan (EAP) (Air Quality Monitoring)

|

EVENT |

ACTION |

|||

|

ENVIRONMENTAL TEAM (ET) |

INDEPENDENT ENVIRONMENTAL CHECKER (IEC) |

ENGINEER’S REPRESENTATIVE ER |

CONTRACTOR |

|

|

ACTION LEVEL |

||||

|

Exceedance for one sample |

1. Identify source, investigate the causes of exceedance

and propose remedial measures; 2. Inform IEC and ER; 3. Repeat measurement

to confirm finding; 4. Increase monitoring frequency to daily. |

1. Check monitoring

data submitted by ET; 2. Check Contractor’s

working method. |

1. Notify Contractor. |

1. Rectify any

unacceptable practice; 2. Amend working

methods if appropriate. |

|

Exceedance for two or more consecutive

samples |

1. Identify source; 2. Inform IEC and ER; 3. Advise the ER on

the effectiveness of the proposed remedial measures; 4. Repeat

measurements to confirm findings; 5. Increase monitoring frequency to daily; 6. Discuss with IEC

and Contractor on remedial actions required; 7. If exceedance

continues, arrange meeting with IEC and ER; 8. If exceedance stops,

cease additional monitoring. |

1. Check monitoring

data submitted by ET; 2. Check Contractor’s

working method; 3. Discuss with ET

and Contractor on possible remedial measures; 4. Advise the ET on

the effectiveness of the proposed remedial measures; 5. Supervise

Implementation of remedial measures. |

1. Confirm receipt of

notification of failure in writing; 2. Notify Contractor; 3. Ensure remedial

measures properly implemented. |

1. Submit proposals

for remedial to ER within 3 working days of notification; 2. Implement the

agreed proposals; 3. Amend proposal if

appropriate. |

|

LIMIT

LEVEL |

||||

|

Exceedance for one sample |

1. Identify source, investigate the causes of exceedance

and propose remedial measures; 2. Inform ER, Contractor and EPD; 3. Repeat measurement

to confirm finding; 4. Increase monitoring frequency to daily; 5. Assess

effectiveness of Contractor’s remedial actions and keep IEC, EPD and ER

informed of the results. |

1. Check monitoring

data submitted by ET; 2. Check Contractor’s

working method; 3. Discuss with ET

and Contractor on possible remedial measures; 4. Advise the ER on

the effectiveness of the proposed remedial measures; 5. Supervise

implementation of remedial measures. |

1. Confirm receipt of

notification of failure in writing; 2. Notify Contractor; 3. Ensure remedial

measures properly implemented. |

1. Take immediate

action to avoid further exceedance; 2. Submit proposals

for remedial actions to IEC within 3 working days of notification; 3. Implement the

agreed proposals; 4. Amend proposal if

appropriate. |

|

Exceedance for two or more consecutive

samples |

1.Notify IEC, ER, Contractor and EPD; 2. Identify source; 3. Repeat measurement

to confirm findings; 4. Increase monitoring frequency to daily; 5. Carry out analysis

of Contractor’s working procedures to determine possible mitigation to be implemented; 6. Arrange meeting

with IEC and ER to discuss the remedial actions to be taken; 7. Assess

effectiveness of Contractor’s remedial actions and keep IEC, EPD and ER

informed of the results; 8. If exceedance stops, cease additional monitoring. |

1. Discuss amongst

ER, ET, and Contractor on the potential remedial actions; 2. Review

Contractor’s remedial actions whenever necessary to assure their

effectiveness and advise the ER accordingly; 3. Supervise the

implementation of remedial measures. |

1. Confirm receipt of

notification of failure in writing; 2. Notify Contractor; 3. In consultation

with the IEC, agree with the Contractor on the remedial measures to be implemented; 4. Ensure remedial

measures properly implemented; 5. If exceedance

continues, consider what portion of the work is responsible and instruct the

Contractor to stop that portion of work until the exceedance is abated. |

1. Take immediate

action to avoid further exceedance; 2. Submit proposals

for remedial actions to IEC within 3 working days of notification; 3. Implement the

agreed proposals; 4. Resubmit proposals

if problem still not under control; 5. Stop the relevant

portion of works as determined by the ER until the exceedance is abated. |

Appendix E

Event

and Action plan (EAP) (Noise Monitoring)

|

EVENT |

ACTION |

|||

|

ENVIRONMENTAL TEAM (ET) |

INDEPENDENT ENVIRONMENTAL CHECKER (IEC) |

ENGINEER’S REPRESENTATIVE ER |

CONTRACTOR |

|

|

Action Level |

1.

Identify source, investigate the causes of exceedance and propose remedial measures; 2. Notify IEC and Contractor; 3. Report the results

of investigation to the IEC, ER and Contractor; 4. Discuss with the

Contractor and formulate remedial measures; 5. Increase

monitoring frequency to check mitigation effectiveness. |

1. Review the analysed results submitted by the ET; 2. Review the proposed remedial measures by the

Contractor and advise the ER accordingly; 3. Supervise the implementation of remedial

measures. |

1. Confirm receipt of notification of failure in

writing; 2. Notify Contractor; 3. Require Contractor

to propose remedial measures for the analysed noise problem; 4. Ensure remedial

measures are properly implemented |

1. Submit noise mitigation proposals to IEC; 2. Implement noise

mitigation proposals. |

Appendix F

Environmental Mitigation Implementation Schedule (EMIS)

Environmental

Mitigation Implementation Schedule

|

EIA Ref. |

EM&A Log Ref. |

Recommended

Mitigation Measures |

Objectives of the Recommended

Measures & Main Concerns to address |

Implementation

Agent |

Location / Timing |

Implementation

Stage |

Requirements and/

or standards to be achieved |

Implementation

Status |

|

Construction Dust

Impact |

||||||||

|

S4.3.10 |

D1 |

The contractor

shall follow the procedures and requirements given in the Air Pollution

Control (Construction Dust) Regulation and Air Pollution Control (Non-road Mobile Machinery) (Emission) Regulation. |

Minimize dust

impact and adverse health effects at the nearby sensitive receivers |

Contractor |

All construction sites |

Construction stage |

·

APCO ·

To control the dust impact to meet HKAQO and TM-EIA criteria |

N/A |

|

S4.3.10 |

D2 |

·

Mitigation measures in form of regular watering under a good site

practice should be adopted. Watering

once per hour on exposed worksites and haul road should be conducted to

achieve dust removal efficiencies of 91.7%. While the above watering

frequencies are to be followed, the extent of watering may vary depending on

actual site conditions but should be sufficient to maintain an equivalent

intensity of no less than 1.3 L/m2 to achieve the dust removal

efficiency. |

Minimize dust

impact at the nearby sensitive receivers |

Contractor |

All construction sites |

Construction stage |

·

APCO ·

To control the dust impact to meet HKAQO and TM-EIA criteria |

N/A |

|

xS4.3.10 |

D3 |

·

Proper watering at exposed spoil should be undertaken throughout the

construction phase; ·

Any excavated or stockpile of dusty material should be covered

entirely by impervious sheeting or sprayed with water to maintain the entire

surface wet and then removed or backfilled or reinstated where practicable

within 24 hours of the excavation or unloading; ·

Any dusty materials remaining after a stockpile is removed should be

wetted with water and cleared from the surface of roads; ·

A stockpile of dusty material should not be extended beyond the

pedestrian barriers, fencing or traffic cones; ·

The load of dusty materials on a vehicle leaving a construction site

should be covered entirely by impervious sheeting to ensure that the dusty

materials do not leak from the vehicle. ·

Where practicable, vehicle washing facilities with high pressure water

jet should be provided at every discernible or designated vehicle exit

point. The area where vehicle washing

takes place and the road section between the washing facilities and the exit

point should be paved with concrete, bituminous materials or hardcores; ·

When there are open excavation and reinstatement works, hoarding of

not less than 2.4m high should be provided and properly maintained as far as

practicable along the site boundary with provision for public crossing. Good site practice shall also be adopted by

the Contractor to ensure the conditions of the hoardings are properly

maintained throughout the construction period; ·

The portion of any road leading only to construction site that is

within 30m of a vehicle entrance or exit should be kept clear of dusty materials; ·

Surfaces where any pneumatic or power-driven drilling, cutting,

polishing or other mechanical breaking operation takes place should be

sprayed with water or a dust suppression chemical continuously; ·

Any area that involves demolition activities should be sprayed with

water or a dust suppression chemical immediately prior to, during and

immediately after the activities so as to maintain the entire surface wet; ·

Any skip hoist for material transport should be totally enclosed by

impervious sheeting; ·

Every stock of more than 20 bags of cement or dry-pulverised fuel ash

(PFA) should be covered entirely by impervious sheeting or placed in an area

sheltered on the top and the 3 sides; ·

Loading, unloading, transfer, handling or storage of bulk cement or

dry PFA should be carried out in a totally enclosed system or facility, and

any vent or exhaust should be fitted with an effective fabric filter or

equivalent air pollution control system ·

Exposed earth should be properly treated by compaction, turfing,

hydroseeding, vegetation planting or sealing with latex, vinyl, bitumen,

shotcrete or other suitable surface stabilizer within six months after the

last construction activity on the construction site or part of the

construction site where the exposed earth lies. |

Minimize dust

impact at the nearby sensitive receivers |

Contractor |

All construction sites |

Construction stage |

·

APCO ·

To control the dust impact to meet HKAQO and TM-EIA criteria |

N/A |

|

S4.3.10 |

D6 |

Implement regular

dust monitoring under EM&A programme during the construction stage. |

Monitoring of dust impact |

Contractor |

Selected rep. dust monitoring station |

Construction stage |

·

TM-EIA |

10 Implemented |

|

11 Construction Noise (Airborne) |

||||||||

|

S5.4.1 |

N1 |

Implement the following good site practices: ·

Only well-maintained plant should be operated on-site, and plant

should be serviced regularly during the construction programme; ·

Machines and plant (such as trucks, cranes) that may be in

intermittent use should be shut down between work periods or should be

throttled down to a minimum; ·

Plant known to emit noise strongly in one direction, where possible,

be orientated so that the noise is directed away from nearby NSRs; ·

Silencers or mufflers on construction equipment should be properly

fitted and maintained during the construction works; ·

Mobile plant should be sited as far away from NSRs as possible and practicable; ·

Material stockpiles, mobile container site office and other structures

should be effectively utilized, where practicable, to screen noise from

on-site construction activities. |

Control construction airborne noise |

Contractor |

All construction sites |

Construction stage |

·

Annex 5, TM-EIAO |

N/A |

|

S5.4.1 |

N2 |

Install temporary

hoarding located on the site boundaries between noisy construction activities

and NSRs. The conditions of hoardings

shall be properly maintained throughout the construction period. |

12 Reduce the construction noise levels

at low-level zone of NSRs through partial screening |

13 Contractor |

14 All construction sites |

15 Construction stage |

·

Annex 5, TM-EIAO |

16 Implemented |

|

S5.4.1 |

N3 |

Install movable

noise barriers (typical design is wooden framed barrier with a

small-cantilevered on a skid footing with 25mm thick internal sound

absorptive lining), acoustic mat or full enclosure, screen the noisy plants

including air compressors, generators and handheld breakers, etc. |

17 Screen the noisy plant items to be

used at all construction sites |

18 Contractor |

19 All construction sites where

practicable |

20 Construction stage |

·

Annex 5, TM-EIAO |

21 N/A |

|

S5.4.1 |

N4 |

Use ‘Quiet plant’ |

22 Reduce the noise levels of plant

items |

23 Contractor |

24 All construction sites where

practicable |

25 Construction stage |

·

Annex 5, TM-EIAO |

26 N/A |

|

S5.4.1 |

N5 |

Loading/ unloading

activities should be carried out inside the full enclosure of mucking out points. |

27 Reduce the noise levels of loading/

unloading activities |

28 Contractor |

29 Mucking out locations |

30 Construction stage |

·

Annex 5, TM-EIAO |

31 N/A |

|

S5.4.1 |

N6 |

Sequencing

operation of construction plants where practicable. |

32 Operate sequentially within the same

work site to reduce the construction airborne noise |

33 Contractor |

34 All construction sites where

practicable |

35 Construction stage |

·

Annex 5, TM-EIAO |

36 N/A |

|

S5.4.1 |

N7 |

Implement a noise

monitoring programme under EM&A programme. |

37 Monitor the construction noise levels

at the selected representative locations |

38 Contractor |

39 Selected rep. noise monitoring

station |

40 Construction stage |

·

TM-EIAO |

41 N/A |

|

42 Water Quality (Construction Phase) |

||||||||

|

S6.9.1.1 |

W1 |

In accordance with

the Practice Note for Professional Persons on Construction Site Drainage,

Environmental Protection Department, 2023 (ProPECC

PN 2/23), construction phase mitigation measures shall include the following: Construction Runoff ·

At the start of site establishment, perimeter cut-off drains to direct

off-site water around the site should be constructed with internal drainage

works and erosion and sedimentation control facilities implemented. Channels (both temporary and permanent

drainage pipes and culverts), earth bunds or sandbag barriers should be

provided on site to direct stormwater to silt removal facilities. The design of the temporary on-site drainage

system will be undertaken by the contractor prior to the commencement of construction; ·

The dikes or embankments for flood protection should be implemented

around the boundaries of earthwork areas.

Temporary ditches should be provided to facilitate the runoff

discharge into an appropriate watercourse, through a silt/ sediment

trap. The sediment/ silt traps should

be incorporated in the permanent drainage channels to enhance deposition rates; ·

The design of efficient silt removal facilities should be based on the

guidelines in Appendix A1 of ProPECC PN 2/23, which

states that the retention time for silt/ sand traps should be 5 minutes under

maximum flow conditions. Sizes may

vary depending upon the flow rate, but for a flow rate of 0.1 m3/s

a sedimentation basin of 30 m3 would be required and for a flow

rate of 0.5 m3/s the basin would be 150 m3. The detailed design of the sand/ silt traps

shall be undertaken by the contractor prior to the commencement of construction; ·

All exposed earth areas should be completed and vegetated as soon as

possible after earthworks have been completed, or alternatively, within 14

days of the cessation of earthworks where practicable. Exposed slope surfaces should be covered by

tarpaulin or other means; ·

The overall slope of the site should be kept to a minimum to reduce

the erosive potential of surface water flows, and all traffic areas and

access roads protected by coarse stone ballast. An additional advantage accruing from the

use of crushed stone is the positive traction gained during prolonged periods

of inclement weather and the reduction of surface sheet flows; ·

All drainage facilities and erosion and sediment control structures

should be regularly inspected and maintained to ensure

proper and efficient operation at all times and particularly following

rainstorms. Deposited silt and grit

should be removed regularly and disposed of by spreading evenly over stable,

vegetated areas; ·

Measures should be taken to minimize the ingress of site drainage into

excavations. If the excavation of

trenches in wet periods is necessary, they should be dug and backfilled in

short sections wherever practicable.

Water pumped out from trenches or foundation excavations should be

discharged into storm drains via silt removal facilities; ·

Open stockpiles of construction materials (for example, aggregates,

sand and fill material) of more than 50m3 should be covered with

tarpaulin or similar fabric during rainstorms. Measures should be taken to prevent the

washing away of construction materials, soil, silt or debris into any

drainage system; ·

Manholes should always be adequately covered and temporarily sealed so

as to prevent silt, construction materials or debris being washed into the

drainage system and storm runoff being directed into foul sewers; ·

Precautions be taken at any time of year when rainstorms are likely,

actions to be taken when a rainstorm is imminent or forecasted, and actions

to be taken during or after rainstorms are summarized in Appendix A2 of ProPECC PN 2/23.

Particular attention should be paid to the control of silty surface

runoff during storm events, especially for areas located near steep slopes; ·

All vehicles and plant should be cleaned before leaving a construction

site to ensure no earth, mud, debris and the like is deposited by them on

roads. An adequately designed and site

wheel washing facilities should be provided at every construction site exit

where practicable. Wash-water should

have sand and silt settled out and removed at least on a weekly basis to

ensure the continued efficiency of the process. The section of access road leading to, and

exiting from, the wheel wash bay to the public road should be paved with

sufficient backfall toward the wheel wash bay to prevent vehicle tracking of

soil and silty water to public roads and drains; ·

Oil interceptors should be provided in the drainage system downstream

of any oil/ fuel pollution sources.

The oil interceptors should be emptied and cleaned regularly to

prevent the release of oil and grease into the storm water drainage system

after accidental spillage. A bypass

should be provided for the oil interceptors to prevent flushing during heavy rain; ·

Construction solid waste, debris and rubbish on site should be

collected, handled and disposed of properly to avoid water quality impacts; ·

All fuel tanks and storage areas should be provided with locks and

sited on sealed areas, within bunds of a capacity equal to 110% of the

storage capacity of the largest tank to prevent spilled fuel oils from

reaching water sensitive receivers nearby; ·

Adopt best management practices; ·

All earth works should be conducted sequentially to limit the amount

of construction runoff generated from exposed areas during the wet season

(April to September) as far as practicable.

|

43 To minimize water quality impact from

the construction site runoff and general construction activities |

44 Contractor |

45 All construction sites where

practicable |

46 Construction stage |

·

Water Pollution Control Ordinance ·

ProPECC PN 2/23 ·

TM-EIAO ·

TM-DSS |

47 Implemented |

|

S6.9.1.2 |

W2 |

Tunnelling Works and Underground Works ·

Cut-&-cover tunnelling work should be

conducted sequentially to limit the amount of

construction runoff generated from exposed areas during the wet season (April to September)

as far as practicable. ·

Uncontaminated discharge should pass through sedimentation tanks prior

to off-site discharge; ·

The wastewater with a high concentration of SS should be treated (e.g.

by sedimentation tanks with sufficient retention time) before discharge. Oil interceptors would also be required to

remove oil, lubricants and grease from the wastewater; ·

Direct discharge of the bentonite slurry (as a

result of D-wall) is not allowed.

It should be reconditioned and reused wherever practicable. Temporary storage locations (typically a

properly closed warehouse) should be provided on site for any unused

bentonite that needs to be transported away after all the related

construction activities area completed.

The requirements in ProPECC PN 2/23 should

be adhered to in the handling and disposal of bentonite slurries. |

48 To minimize construction water

quality impact from tunnelling works |

49 Contractor |

50 All tunnelling portion |

51 Construction stage |

·

Water Pollution Control Ordinance ·

ProPECC PN 2/23 ·

TM-DSS ·

TM-EIAO |

52 N/A |

|

S6.9.1.3 |

W3 |

Sewage Effluent ·

Portable chemical toilets and sewage holding tanks are recommended for

handling the construction sewage generated by the workforce. A licensed contractor should be employed to

provide appropriate and adequate portable toilets and be responsible for

appropriate disposal and maintenance. |

53 To minimize water quality from sewage

effluent |

54 Contractor |

55 All construction sites where

practicable |

56 Construction stage |

·

Water Pollution Control Ordinance ·

TM-DSS |

57 Implemented |

|

S6.9.1.5 |

W4 |

Groundwater from Potential Contaminated Area: ·

No direct discharge of groundwater from contaminated areas should be adopted. ·

A discharge license under the WPCO through the Regional Office of EPD for groundwater discharge should be

applied. Prior to the excavation works within these

potentially contaminated areas, the

groundwater quality should be reviewed during the process of discharge license application. The

compliance to the

Technical Memorandum on Standards for

Effluents Discharged into Drainage on

Sewerage Systems, Inland and Coastal Waters (TM-DSS) and the existence of

prohibited substance should be confirmed. If the

review results indicated that the groundwater to be generated from the excavation works would be

contaminated, the contaminated groundwater should

be either properly treated in compliance with

the requirements of the TM-DSS or properly recharged into the ground. ·

If wastewater treatment is deployed, the wastewater treatment unit shall deploy suitable treatment process

(e.g. oil interceptor / activated carbon)

to reduce the pollution level to an acceptable standard and remove any prohibited substances

(e.g. TPH) to undetectable range. All treated

effluent from wastewater treatment plant

shall meet the requirements as stated in TM-DSS and should be discharged into the foul sewers. ·

If groundwater recharging wells are deployed, recharging wells should be installed as appropriate for recharging

the contaminated groundwater back into

the ground. The recharging wells should be

selected at places where the groundwater quality will not be affected by the recharge operation as

indicated in the Section 2.3 of TM-DSS. The baseline

groundwater quality shall be determined prior

to the selection of the recharge wells, and submit a working plan (including the laboratory

analytical results

showing the quality of groundwater at the proposed recharge location(s) as

well as the pollutant levels of groundwater to be recharged) to EPD for

agreement. Pollution levels of groundwater to be recharged shall not be

higher than pollutant levels of ambient groundwater at the recharge well.

Prior to recharge, any prohibited substances such as TPH products should be

removed as necessary by installing the petrol interceptor. |

58 To minimize groundwater quality

impact from contaminated area |

59 Contractor |

60 Excavation areas where contamination

is found |

61 Construction stage |

·

Water Pollution Control Ordinance ·

TM-DSS ·

TM-EIAO |

62 N/A |

|

S6.9.1.6 |

W6 |

Accidental Spillage In order to prevent accidental spillage of chemicals, the following is

recommended: ·

All the tanks, containers, storage area should be bunded and the

locations should be locked as far as possible from the sensitive watercourse

and stormwater drains; ·

The Contractor should register as a chemical waste producer if

chemical wastes would be generated.

Storage of chemical waste arising from the construction activities

should be stored with suitable labels and warnings. Disposal of chemical wastes should be conducted in compliance with the

requirements as stated in the Waste Disposal (Chemical Waste) (General)

Regulation. |

63 To minimize water quality impact from

accidental spillage |

64 Contractor |

65 All construction site where

practicable |

66 Construction stage |

·

Water Pollution Control Ordinance ·

ProPECC PN 2/23 ·

TM-EIAO ·

TM-DSS |

67 N/A |

|

68 Waste Management (Construction Waste) |

||||||||

|

S7.4.1 |

WM1 |

On-site sorting of C&D material ·

Geological assessment should be carried out by competent persons on

site during excavation to identify materials which are not suitable to use as

aggregate in structural concrete (e.g. volcanic rock, Aplite dyke rock,

etc.). Volcanic rock and Aplite dyke

rock should be separated at the source sites as far as practicable and stored

at designated stockpile area preventing them from delivering to crushing

facilities. The crushing plant

operator should also be reminded to set up measures to prevent unsuitable

rock from ending up at concrete batching plants and be turned into concrete

for structural use. Details regarding

control measures at source site and crushing facilities should be submitted

by the Contractor for the Engineer to review and agree. In addition, site records should also be

kept for the types of rock materials excavated and the traceability of

delivery will be ensured with the implementation of Trip Ticket System and

enforced by site supervisory staff as stipulated under DEVB TC(W) No. 6/2010

for tracking of the correct delivery to the rock crushing facilities for

processing into aggregates.

Alternative disposal option for the reuse of volcanic rock and Aplite

Dyke rock, etc. should be explored. |

69 Separation of unsuitable rock from ending

up at concrete batching plants and be turned into concrete for structural use |

70 Contractor |

71 All construction sites |

72 Construction stage |

·

DEVB (W) No. 6/2010 |

73 N/A |

|

S7.5.1 |

WM2 |

Construction and Demolition Material ·

Maintain temporary stockpiles and reuse excavated fill material for

backfilling and reinstatement; ·

Carry out on-site sorting; ·

Make provisions in the Contract documents to allow and promote the use

of recycled aggregates where appropriate; ·

Adopt ‘selective demolition’ technique to demolish the existing

structures and facilities with a view to recovering broken concrete

effectively for recycling purpose, where possible; ·

Implement a trip-ticket system for each works contract to ensure that

the disposal of C&D materials is properly documented and verified; and ·

Implement an enhanced Waste Management Plan similar

to ETWBTC (Works) No. 19/2005 – “Environmental Management on

Construction Sites” to encourage on-site sorting of C&D materials and to

minimize their generation during the course of construction. |

74 Good site practice to minimize the

waste generation and recycle the C&D materials as far as practicable so as to reduce the amount for final disposal |

75 Contractor |

76 All construction sites |

77 Construction stage |

·

Land (Miscellaneous Provisions) Ordinance ·

Waste Disposal Ordinance ·

ETWB TCW No. 19/2005 |

78 N/A |

|

S7.5.1 |

WM3 |

C&D Waste ·

Standard formwork or pre-fabrication should be used as far as

practicable in order to minimize the arising of

C&D materials. The use of more

durable formwork or plastic facing for the construction works should be

considered. Use of wooden hoardings

should not be used, as in other projects.

Metal hoarding should be used to enhance the possibility of

recycling. The purchasing of

construction materials will be carefully planned in order to avoid over

ordering and wastage; ·